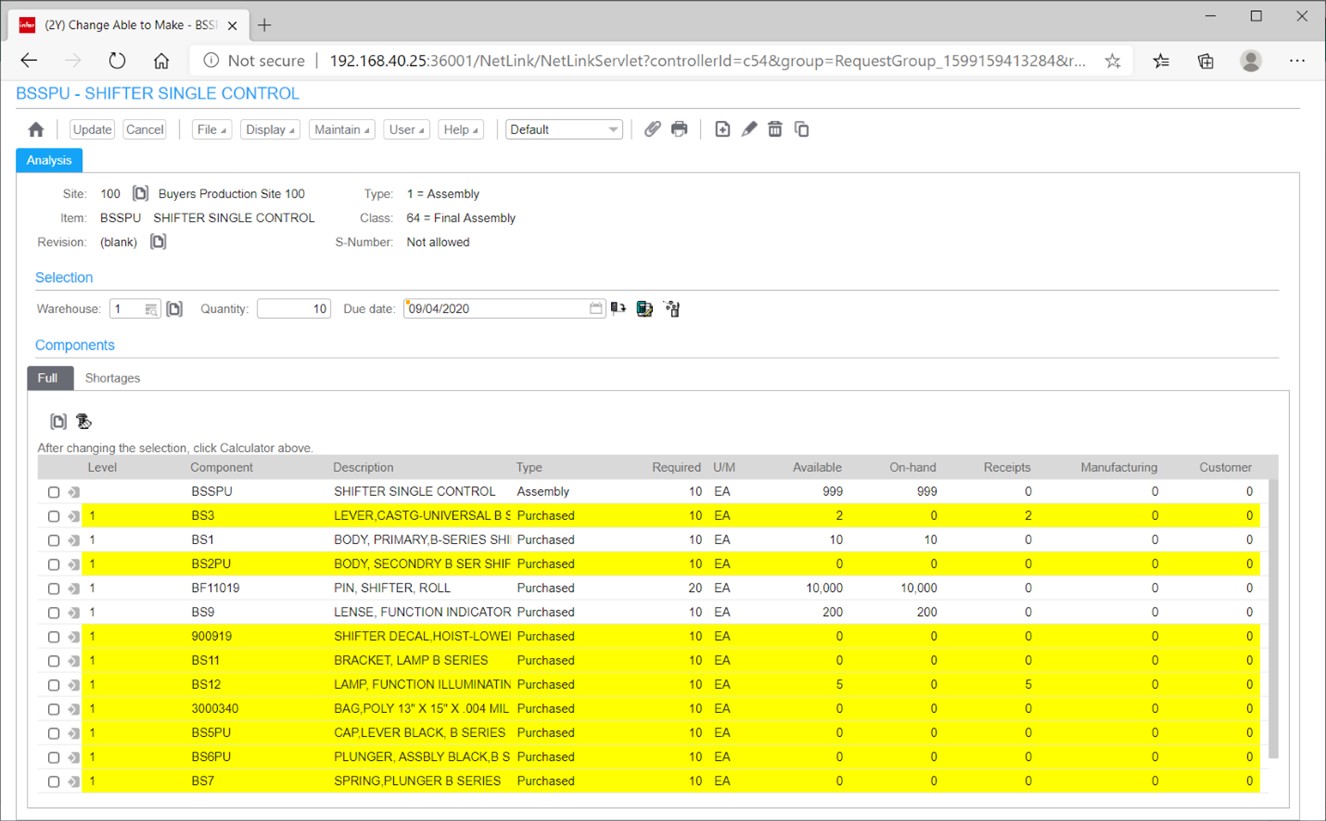

Planning your manufacturing/assembly operation is a challenge you have to meet every day. Relying on tools like Materials Requirements Planning (MRP), Master Production Schedule Planning (MPSP), Capacity Requirements Planning (CRP), and Advanced Planning Systems (APS) may be impractical in your highly engineered, make-to-order environment. Your question is simple, “Based on what I have on hand, what am I able to make?”

Able to Make (A2M) is designed to assist material planners with analyzing component availability for all levels of an indented bill-of-material. The user enters the item, warehouse, quantity to manufacture, and due date. An inquiry screen follows displaying all lower levels of material components analyzed for availability. Now your planning operation can easily observe what you can make, and make informed decisions on what to make, and when to make it!